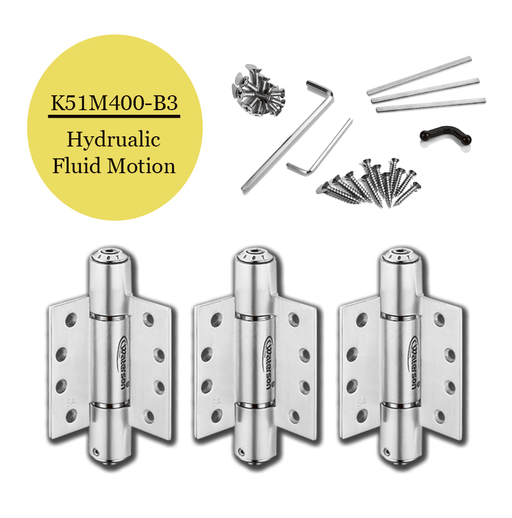

Key Specifications of Waterson Heavy Duty Door Closer Include:

- Door Height: Up to 6 ft (2 pcs) / 7 ft (3 pcs) / 8 ft (4 pcs)

- Door Weight: Up to 150 lbs (2 pcs) / 260 lbs (3 pcs) / 330 lbs (4 pcs)

- Gate Thickness: 1 ⅜” to 2 ¼”

- Material: Stainless Steel SS304 - SS316 available on selected models

- Finish: Satin Stainless Steel (US32D), Flat Black (US19), Satin Brass (US4), Dark Satin Bronze (695). Custom finishes available

- Type: Mechanical Self-Closing (A-C) or Hydraulic Soft-Closing (B-D)

- Features: Fire Rated (A-B Models), Hold Open (C-D Models)

Application: High-traffic door openings including main entrances, corridor doors, stairwell doors, and service doors requiring controlled closing and durability.

What Is the Difference Between Standard and Heavy Duty Door Closers?

Standard door closers were never designed for the environments you face:

- Light-duty capacity: Limited to interior doors with lighter panels.

- Shorter cycle life: Wear faster when exposed to continuous traffic.

- Basic adjustability: Only sweep and latch, with narrow tuning range.

- Minimal compliance: Often lack fire-rating or Grade 1 certification.

Limited durability: Susceptible to fatigue under wind or oversized loads.

Waterson heavy duty door closers, by contrast, are engineered for the demands that break standard hardware:

- Weight loading: Handles doors weighing 260–440 lbs or more with stability and precision.

- 3 in 1 Design: Combines door closer, spring hinge, and optional hold-open in one low-profile, unobtrusive component.

- High-cycle endurance: Tested for 1.000.000 cycles of openings in hospitals, schools, and transit facilities.

- Certified compliance: ANSI/BHMA A156.4 Grade 1 and UL 3-hour fire-rated listings.

- Adjustable speed control: The numerical tension system allows you to fine-tune sweep, latch, and backcheck for precise closing performance.

- Material strength: Stainless steel 304 & 316 with corrosion resistance, wind shear, and repeated force.

Any Other Different Types of Door Closers?

- Surface Mounted Closers – Most common; mounted on the door/frame surface. Available in standard, parallel arm, and top jamb configurations.

- Concealed Closers – Installed within the door or frame; preferred when aesthetics and flush appearance matter.

- Floor Closers – Built into the floor with pivot arms; ideal for heavy glass or oversized entryways.

- Specialty Heavy Duty Door Closer (like Waterson)– Such as extra heavy duty door closers with reinforced mechanisms or heavy duty door closers with hold open functions for fire doors, stairwell entries, or industrial gates.

How to Choose the Correct Door Closer?

Start with the door itself. Weight, width, and usage always dictate the closer. A 90 lb office leaf is not a 280 lb stairwell fire door — undersizing leads to misalignment, failed inspections, and callbacks.

- Door weight & size: Follow BHMA templates. Heavy doors require a heavy duty door closer to keep force consistent.

- Traffic level: High-cycle areas (schools, hospitals, transit) demand Grade 1 hardware.

Code compliance: Stairwell and shaft doors need UL fire-rating; accessible routes must meet ADA 5-lb opening force. - Environment: Exterior wind calls for reinforced backcheck; coastal or humid climates need stainless steel.

- Installation conditions: Check frame depth, clearance, and mounting type (surface, concealed, floor). The closer must fit the opening, not fight it.

In short: size it right, verify compliance, match the environment, and respect the installation. Only then do you consider extras like hold-open or aesthetics.

How to Install Waterson Heavy Duty Door Closer?

Start with door height and weight. Both determine the correct number of hinges for safe, code-compliant installation.

- Up to 60" height: Use 2 hinges.

- Over 60" to 90" height: Use 3 hinges.

- Over 90" to 120" height: 4 hinges recommended.

Door weight matters too:

- With three hinges, Waterson supports doors from 150–330 lbs.

- For heavier leaves 260–440 lbs, four hinges are required.

Always follow the manufacturer’s specification. If the door calls for three hinges, use three Waterson self-closing heavy duty door closers. Don’t over- or under-spec — installation must align with tested performance.

Waterson Heavy Duty Door Closer Common Applications

- Fire-rated stairwell door closers

- Exit door closers

- Hospital corridor door closers

- School corridor door closers

- High wind exterior gate closers

- Elevator shaft door closers

- Smoke barrier door closers

- Industrial oversized door closers

- High traffic hotel door closers

- Commercial entry door closers